the "centrifugal cast process" is acknowledged to be the best method. It possesses the bearing metal qualities that cause skin healing after abrasion and a structure that is readily wetted by oil and retains an oil film. Corrosion resistance is further improved by adding chromium in the metal. In the centrifugal casting process, the molten metal is poured into a metal mould or die which is revolving at a high speed. The centrifugal force causes the metal to distribute itself evenly around the die. The resulting casting are of much finer grain and free from blow holes or porosity. A further important advantage is that the impurities, being lighter than the iron, are forced centrifugally to the bore surface from which they are removed by machining.

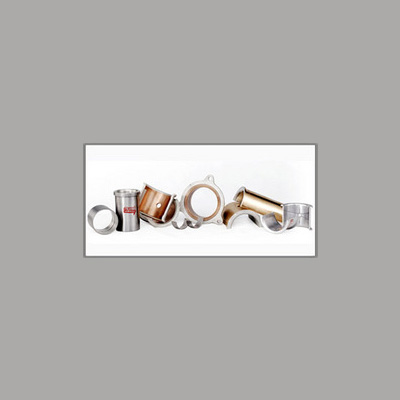

Brand Engine Bearings are made up of best quality steel…

PISTONS are manufactured in a new alloy of exceptional wear…

Gudgeon Pins / Piston Pins for single cylinder engine applications…

valve seat inserts - our high chrome alloy, heavy duty,…

Air cooled cylinder barrels made from special " Shell Moulding…

Agra Engineering Company established in 1953 is an ISO 9001 2008 company that exports to 86 countries. Some of the engine parts that we export are for Automobile Tractors and Trucks like Toyota Mercedes Cheverolet John Deere Daihatsu Ursus International Harvestor.

C-5, Laxmi Towers, BKC, Bandra (east),

Mumbai, Maharashtra

Phone: +91 9102222886389, 9102222886389